Smart Hardware Integration with Advanced Robot Programming Technologies for Efficient Reconfiguration of Robot Workcells

Dec 1, 2020·,,,,,,,,,,,,,·

1 min read

Timotej Gašpar

Miha Deniša

Primož Radanovič

Barry Ridge

T. Rajeeth Savarimuthu

Aljaž Kramberger

Marc Priggemeyer

Jürgen Roßmann

Florentin Wörgötter

Tatyana Ivanovska

Shahab Parizi

Žiga Gosar

Igor Kovač

Aleš Ude

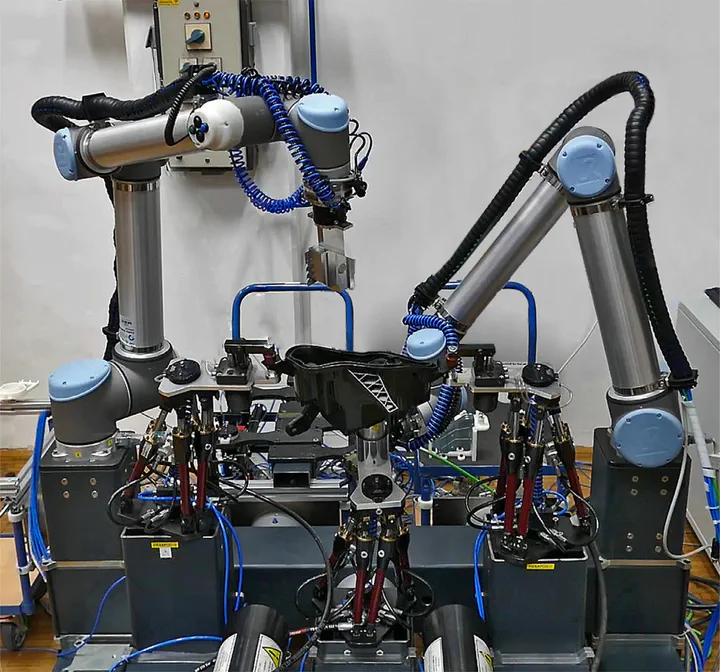

The reconfigurable robot workcell in a configuration where it assembles an automotive headlight.

The reconfigurable robot workcell in a configuration where it assembles an automotive headlight.Abstract

The manufacturing industry is seeing an increase in demand for more custom-made, low-volume production. This type of production is rarely automated and is to a large extent still performed manually. To keep up with the competition and market demands, manufacturers will have to undertake the effort to automate such manufacturing processes. However, automating low-volume production is no small feat as the solution should be adaptable and future proof to unexpected changes in customers’ demands. In this paper, we propose a reconfigurable robot workcell aimed at automating low-volume production. The developed workcell can adapt to the changes in manufacturing processes by employing a number of passive, reconfigurable hardware elements, supported by the ROS-based, modular control software. To further facilitate and expedite the setup process, we integrated intuitive, user-friendly robot programming methods with the available hardware. The system was evaluated by implementing five production processes from different manufacturing industries.

Type

Publication

Robotics and Computer-Integrated Manufacturing